Eco Composite Flooring

– Where Sustainability Meets Performance

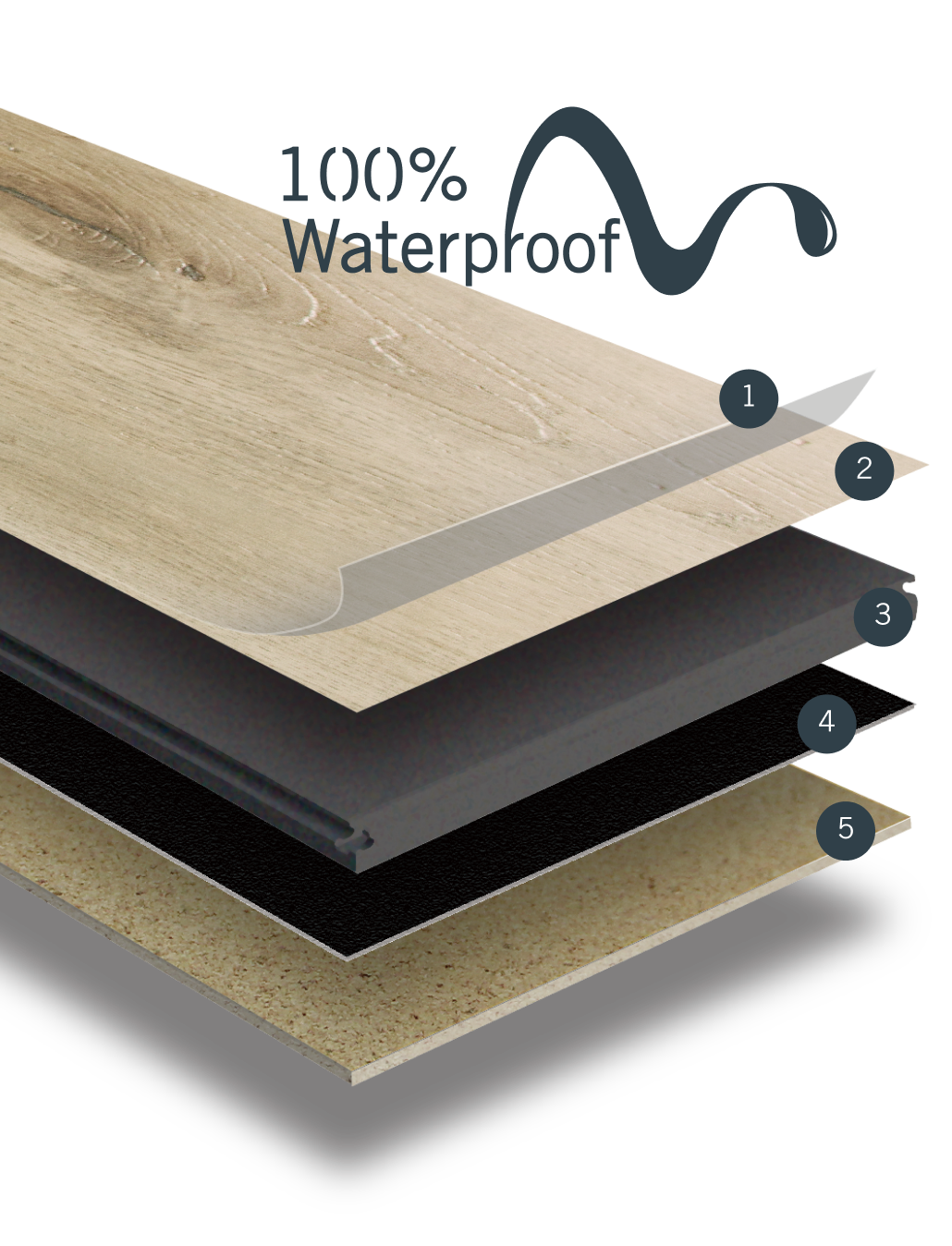

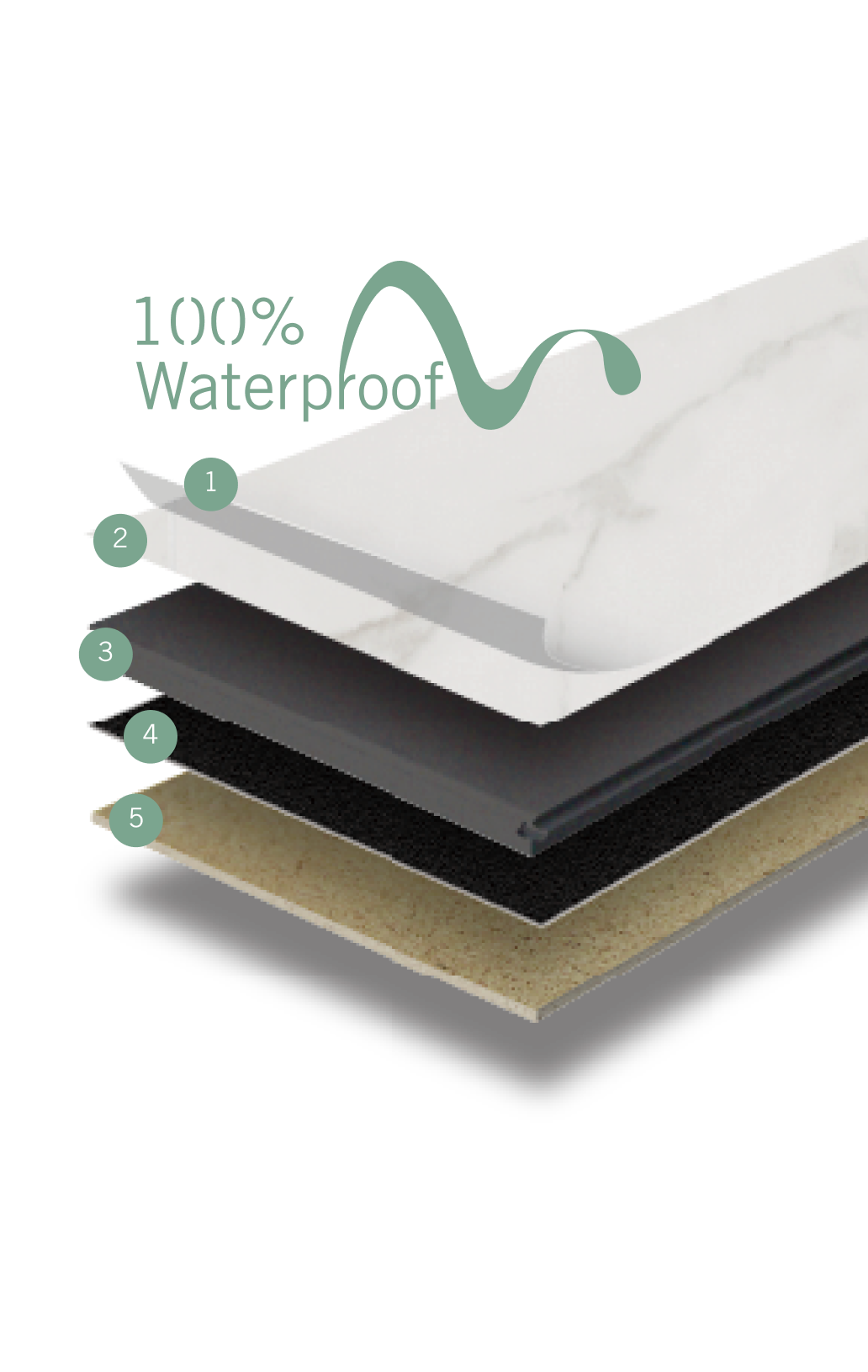

Tenacity Eco Composite Flooring combines sustainability and performance with a TriTec surface finish that offers up to 10 times more scratch resistance than traditional PVC floors. Fully waterproof and stain-resistant, it’s ideal for high-traffic areas like kitchens and bathrooms. Made with up to 80% natural materials and 50% post-consumer recycled content, its PVC-free core is both eco-friendly and durable, with cork backing that reduces plastic use by up to 15kg per 100m2 installation.

Perfect for both residential and commercial spaces, Tenacity is Class 33 rated for heavy use and installs easily over large areas without transition moldings. Its durability, sustainability, and ease of installation make it a smart choice for modern environments.